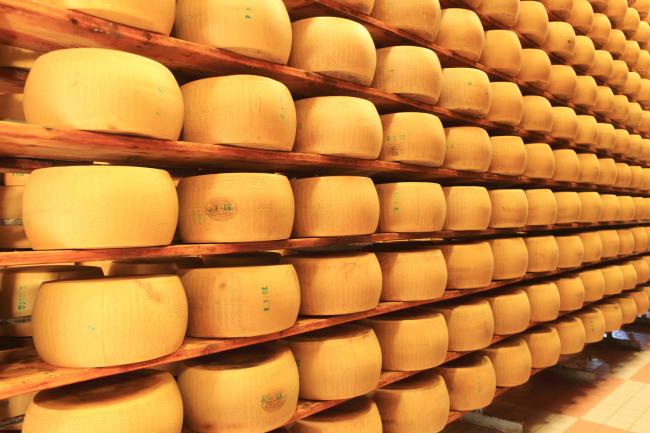

Food Chain of Parmigiano Reggiano: Enhancement of products to zero waste

The integrated use of the two prototypes will allow the extraction from the solid part of the digestate of:

• A fertiliser containing ammonium salts and a non contaminated amendment which provides nutrients and structural benefits, improving soil fertility, increasing retention of water and of nutrients, particularly calcium, potassium and phosphorus.

• A fuel: the synga

• Plyphenolic compounds (biomolecules with high added value), which can be used in the food industry, with an antioxidative function to protect cells from damages provoked by free radicals.

• Digestate Collection and storage

• Digestate treatment using two prototypes ("evapoconcentratore" carbonizer): the combined use of the two prototypes will enable the conversion of the digestate into a fertilizer, organicfertilizer and nitric acid; in energy from renewable sources with low emission of pollutants and antioxidants contained in the bio-oil fraction (tar), obtained as a result of pyrolysis, for their reuse for food purposes.

• The use of biochar as a soil enriched agronomic rating.

• Laboratory analysis to characterize the products obtained.

1) MANAGEMENT ACTION (STUARD, SSICA, UCSC, CFSIVT, SCVSA)

Stuard will assume the role of coordinator of the GO, planning and implementing all the initiatives required to achieve the results provided by the Plan For this reason, it will employ its own, technical and administrative staff, qualified and equipped with multi-year experience in the coordination of research, experimentation and dissemination projectactivities.

The staff will operate in accordance with specific management procedures and operational to ensure a proper conduct of the activties (staff training, evaluation of suppliers, implementation of project activities, verification and assessment of compliance of the operations and results obtained with respect to the expected results).

From the operational point of view, Stuard as Head of Plan (RP) will coordinate:

• overall activities;

• animation and dissemination actions, described in the plan.

2) STUDY ACTIONS NEEDED FOR THE IMPLEMENTATION OF THE PLAN (MARKET, FACTORY, BUSINESS PLAN, ECC): (SCVSA)

The aim is to evaluate the economic sustainability of the project for agronomic, energetic and food use of the products obtained through digestate treatment. The alternative use of digestate, proposed under this project, involves a significant reduction in the management and environmental costs of cogeneration residues and market value enhancement of the products resulting from the conversion process of such residues, such as ammonium salts, biochar, thermal energy, and polyphenols usable in food supplementation. In addition in order to have a positive impact on the economy of the agro-energy supply chain, the project will result in a number of beneficial effects on human well-being through the generation of positive externalities.

Costs and benefits will be assessed at every level of the chain in the perspective of optimizing, in a long-term perspective, the economic efficiency of technological transformation.

Action 3.1 Collected and Storage of digestate (Stuard, and Farms). Stuard will be responsible for collecting the digestate product from Begani farm biogas plant and collecting the ammonium salts obtained from the treatment process of the digested (prototype SSICA) that will be accumulated in special containers and subsequently used for the production of "fertilizer mixtures" with the biochair. Farmers will support Stuard through the provision of conveyors and mixers, in the transport of materials from the place of production to the field of use in the field.

Stuard will handle the digestate from the company Begani to the technological center of the University of Parma, where the carboniser is located, and the subsequent transport of the biochair to the experimental sites.

Action 3.2 SSICA prototype digestion treatment (SSICA)

- 2 EFFECT EVAPORATORS AND TWO STAGES:

The system operates two counter-current effects, in which the product to concentrate enters in the Second Effect (II Effect / 1st Stage) and transferred to the First Effect to achieve the desired concentration.

- EVAPORATOR CONDENSATION CONCENTRATION:

The system is designed to concentrate on coated spiral polymer osmosis (RO) membranes.

This section will be 'double pass' to ensure the highest concentration possible and at the same time the best quality of the permeate.

Process management and control of operating parameters must be governed by a software

and control panel with a high level of automation.

Action 3.3 Carbonisation and subsequent carbonization (CFSIVT, SCVSA)

CFSIVT (Tadini) has in use an innovative micro carboniser (patent WO 215/018742), equipped with a specific feed-back system and biomass. The technological innovation of the product consists of the possibility of carbonization, without pretreatment, of waste materials as a sustainable source of thermal and electrical energy, using a dual power supply and a control system that optimizes the proportions of input materials. But true innovation lies in the product obtained by carbonization, a process that converts matter. The plant is fully automated, controlled by a control unit (PLC) that automatically manages all thermodynamic cycles without operator supervision. The software is designed to look for the ideal conditions for optimizing the process according to the different available biomass, based on

temperature, pressure and flow rates, detected by sensors located at various points in the plant. Integration with telecommunication systems (ICT) guarantees local and global automation and processing.

Six months are planned for the feeding system, during which it will be biochar product, which will be used for autochthonous harvesting tests at farms.

Action 3.4 Agronomic tests (Stuard, and Farms)

The trial will last two years, the trial fields will be carried out at the Porta Camillo farm and the Stuard Experimental Agricultural Company, while the Begani farm will provide the various fertilizer matrices for the entire duration of the experiment.

From the autumn of 2017 (with the planting of vineyard autumn cereal), farms will be responsible for soil preparation, sowing and crop management in accordance with good agricultural practices of PGIs in collaboration with Experimental Stuard agricultural technicians.

Experts from the Stuard Experiment Company will assist and assist farmers during soil preparation, planting, and handling for the entire duration of the project while performing the preparation of the various fertilizer matrices together. The Stuard Experimental Farm will also focus on the testing and definition of the experimental protocol, the choice of varieties to be included in the experimental fields, the design of field patterns and seed detection, and the distribution of the various fertilizer matrices in collaboration where necessary, with farms.

In each company, a field with an experimental design will be created that involves the use of two different cycles of rotation:

- at Porta Camillo Farm (Autumn 2017) 1st year wheat, second year protein pea

- at the Experimental Agricultural Stuard (Spring 2018) first year tomato, second year wheat.

Action 3.5 Laboratory Analysis (UCSC, SCVSA, SSICA)

Biochar Analysis for Its Use as Amendment (SCVSA)

SCVSA will perform basic analyzes for biochar and soil characterization.

Polyphenols in TAR (UCSC)

Digestated Analysis and Prototype Products SSICA (SSICA)

Action 3.6 Draft annual reports, detailing the technical and managerial details of each business test and the results achieved (year by year) (STUARD, UCSC, CFSIVT, SCVSA)

For each of the companies and actions, a report will be drawn up by the partners who will annually record all the results obtained and will be the basis of any improvements to be introduced for the following year.

Action 3.7 Drawing Guidelines for Application and Spreading Practices and / or Combination of Test Practices. (STUARD)

At the end of the planning period, a technical and agronomic account will be produced of the activity carried out in each company, showing the successes and possible failures of the tested techniques in the different types of soil. The aim is to provide a reading key that can make the contextualization of the practices easier, even and above all, depending on the company's features.

Action 3.8 Data Collection and LCA (UCSC, STUARD, CFSIVT, SCVSA)

Sampling evaluation agronomic enhancement

Sampling evaluation of energy enhancement

Sampling Food Valuation Evaluation

4) DISSEMINATION ACTION

During the PARMORIZATION project various dissemination and communication activities will be planned and carried out in order to inform the stakeholders about the objectives of the project and the achieved results, allowing them to be transferred.

This action will be based on the following activities:

- Spreading Plan and Strategy: Stuard (CF) Company together with the Scientific Responsible (RS) and the Partners' Responsibilities of G.O. will prepare a detailed planning of communication and dissemination activities, identifying the most appropriate goals and means of communication, modulating both the times and the actions to be taken;

- Definition of visual identity of the project: in order to make the PARMORIZATION project easily recognizable, the image will be coordinated, in line with the objectives of the project and the PSR 2014-2020. Visual identity will include:

• The logo of the project

• The template for presentations, for PDF documents (to be used for press releases, reports, etc.), for brochures and other dissemination material,

All awareness and promotion material will then report the PARMORIZATION program logo and the references of the contribution of the PSR Regione Emilia Romagna 2014-2020;

- Dissemination of the intermediate and final results of the project to the press and the media: PARMORIZATION project partners, in co-ordination with the Head of Rails and the Scientific Manager, will use the main channels of communication and the network to work with the media in order to guarantee better dissemination of project results.

| Titolo/Descrizione | Url | Tipologia |

|---|---|---|

|

Sito web del progetto

|

Sito web

|

|

|

LINEE GUIDA del progetto

|

Materiali utili

|

|

|

Relazione tecnica finale

|

Materiali utili

|

|

|

Video Evento del 1 marzo 2019

|

Materiali utili

|

Parmorizzazione: Valorizzazione dei sottoprodotti a scarti zero della filiera del Parmiggiano Reggiano

Nel progetto in questione il digestato bovino prodotto dall’impianto di biogas dell’azienda agricola Begani di Palanzano (PR), è stato processato da un prototipo concentratore,…